Types of Gloves

-

Glovmaster > Types of Gloves

Types of Gloves

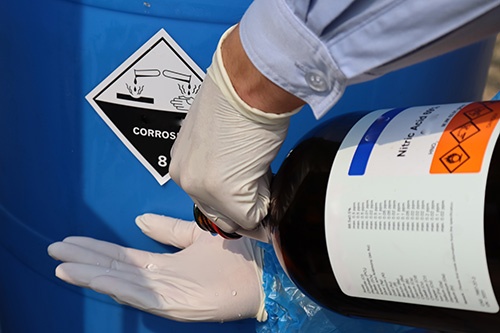

Most hand injuries from exposure at work are easily preventable by wearing protective gloves. A lot of people have the concept of “one glove fits all” but realistically, there is no ONE such glove. There are many different types of work environment, depending on the industry or application, which involves different types of chemicals and solvents. With these different scenarios, different types of gloves are made to best match each individual situation.

Matching the right glove to a specific work environment is the first step towards protection for everyone’s health and safety. This is the exact reason why it is important to choose gloves according to the line of work, as well as the material being handled, and the hazard involved during work.

Once the chemical hazards in a particular environment has been identified, the next step is to match the hazards to the glove material. Glove materials differ in a lot of factors including their protective properties, texture, flexibility, and even thickness.

Disposable, or reusable?

Disposable gloves are meant for single-use only, and should never be reused. They are intended for protection against accidental contact rather than in work environment where long-term hazardous exposure is expected or foreseen. Disposable gloves provide good dexterity while retaining high touch sensitivity. However, they may tear or perforate more easily when pressure is applied.

Reusable gloves are gloves that have thickness between 457 to 711 microns. They can be used repeatedly, provided that they are well-taken care of. They provide more protection against hazardous exposure and do not tear as easily against abrasion. However, they are may interfere with dexterity and touch sensitivity depending on the glove texture and thickness. Reusable gloves need to be thoroughly washed and dried inside out before the next use to avoid contamination against skin from the previous use. Regardless of the term ‘reusable’, they do not last forever and should be checked for damages before each use.

Types of gloves materials

| NITRILE | LATEX | POLYVINYL CHLORIDE (PVC) |

|---|---|---|

| Most suitable for general use | Protects against biohazard, inorganic chemicals, and water-based materials | Good option to replace latex gloves for people with allergic reactions towards latex |

| Provide good high touch sensitivity | Made from natural rubber and intended for incidental contact | Offers standard protection against most chemicals |

| Are extra strong | Very tactile and are hence preferred for sensitive applications like surgery | Less durable than latex or nitrile |

| Soft and comfortable to wear, offering an excellent fit | Durable, flexible, and comfortable to wear | Less sensitive to touch |

| Resistant towards: solvents, oils, grease, hydrocarbons, some acids and bases | Not suitable for handling organic solvents, oils, grease, and hydrocarbon derivatives | Not ideal for organic solvents and water-based solutions |

| Perforation and tears are easily detectible | Hard to detect lacerations or perforations in latex | Production, use, and disposal of PVC results in the release of toxic, chlorine-based chemicals |

| Protects against biohazard | Main disadvantage is that latex can cause skin allergies and reactions | If not properly disposed, can cause build-up of toxin in the environment |

| Can be used safe for both incidental and extended contact | Not bio-degradable | |

| Not suitable to be worn while dealing with ketones, oxidizing acids, and organic compound containing nitrogen | Very cost-effective | |

| One disadvantage is that they have less tactile sensitivity than latex gloves | ||

| Nitrile is also not as cheap to produce compared to PVC |

Six Common Chemicals that Require Disposable Gloves

Wood Stains

Wood stains come in a variety of compositions and consistencies. Some are semi-transparent, and others are intended to create a thick coating over the wood. Because of the variety of wood stain products on the market, specific stains may have multiple hazardous chemicals in them. Some chemicals commonly found in wood stains are ethylene glycol, sodium hydroxide, ethyl alcohol, latex and 1,4-dioxane. Industrial grade nitrile, latex or vinyl disposable gloves provide chemical resistance and effective protection depending on the chemical and duration of use. Consumers should always follow manufacturers label instructions and take steps to avoid exposure to chemicals by using the recommended barrier protection, such as disposable gloves.

Pesticides

Naphthalene, paradichlorobenzene, and capsaicin are chemicals commonly found in pesticides and are among the 6 types of chemicals that require disposable glove use. It is important to use the right glove for the right job for the best protection. For example, industrial grade latex, nitrile and vinyl disposable gloves are resistant to the chemical naphthalene and are all suitable to use when handling this chemical; but only nitrile gloves. In fact, premium nitrile gloves are three times more puncture-resistant than latex and are more chemical resistant than latex or vinyl.

Specialty Chemicals

Specialty chemicals are produced to serve a specific function and may be composed of a single chemical or a blend. Iodine, printing ink, lubricants and plastics are chemicals that require disposable glove use. These specialty chemicals often have an influence on the end product in the manufacturing process and are commonly used in the oil industry, agriculture, electronics, construction and in consumer goods, such as detergents, perfumes and paper items. Because these blends vary depending on the application, specialty chemicals should always be handled with care, which means wearing disposable gloves and other personal protective equipment (PPE).

Perchloroethylene

What is perchloroethylene? This chemical is a non-flammable, colorless, volatile organic compound frequently used in dry cleaning applications. It is also known as tetrachloroethylene, PCE and PERC. While dry cleaning services are the most common use for PERC, it is also used to manufacture other chemicals, such as chlorofluorocarbons, rubber coatings, insulating fluid or cooling gas for electrical transformers, solvent soaps, printing inks, adhesives, leather treatments and automotive cleaners, among others.

Exposure to perchloroethylene is common in work environments such as dry cleaning, metal degreasing, chemical production, rubber coating, or textile factories. Although most PERC-related health problems are caused by inhalation, the chemical may cause irritation after direct contact with the skin.

Lacquer and Paint Thinners

Lacquer and paint thinners are harsh solvents that should not be handled without the correct personal protective equipment (PPE). This is because these substances, which are used in the construction, automotive, retail and maritime industries, present several health risks when they are not handled safely. If workers use paint and lacquer thinners without gloves, they may experience dermatitis, skin irritation and numbness in the areas that come in contact with the solvents. With repeated exposure to the chemicals, the side effects become more severe, ranging from liver disease to an increased risk of cancer, as indicated by material safety data sheets (MSDSs) for these solvents.

Salon Chemicals

Hazardous chemicals are found in many industries and products, and the beauty industry is no exception. Acetone, formaldehyde, trichloroethylene, dibutyl phthalate and toluene are among the six common chemicals that require disposable gloves. These chemicals are in many beauty industry products including nail polish, nail polish remover, nail and hair bonding glue, hair dye and hair spray. Workers in the beauty industry handle potentially toxic chemicals on a daily basis and should don the right personal protective equipment based on the chemicals used. Because chemical concentrations may vary, it is important to check the safety data sheet issued by the manufacturer and conduct in-house testing to determine the safe exposure time.

Nitrile gloves such as Nitrile Examination Glove are more chemical resistance than latex or vinyl and offer three times more puncture-resistant than latex. Although nitrile gloves provide excellent barrier protection against many common salon chemicals, it is crucial to understand the recommendations for each solution.